Continuous Wave Laser Technology Improves In-House Mold Maintenance Capabilities

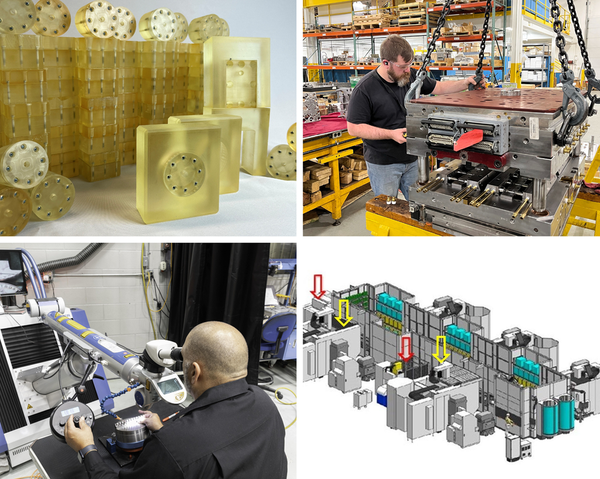

Headquartered in Quincy, Illinois, Titan International Inc. (Titan) offers a full line of wheels, tires and undercarriage products for a wide variety of off-road equipment. With various locations and a global network, Titan offers equipment that manufacturers and operators can count on for durable products as well as quality service.

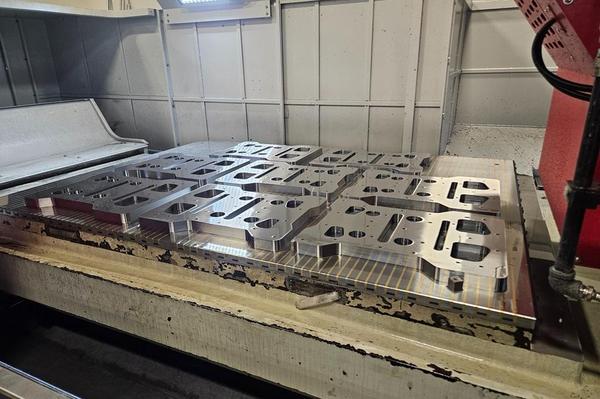

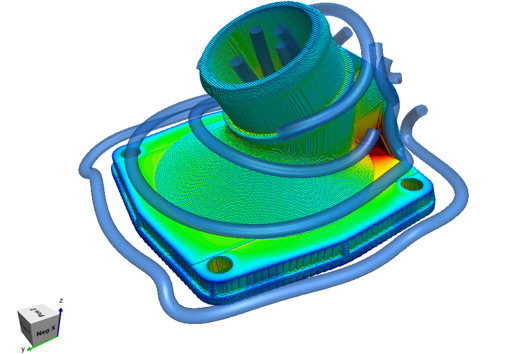

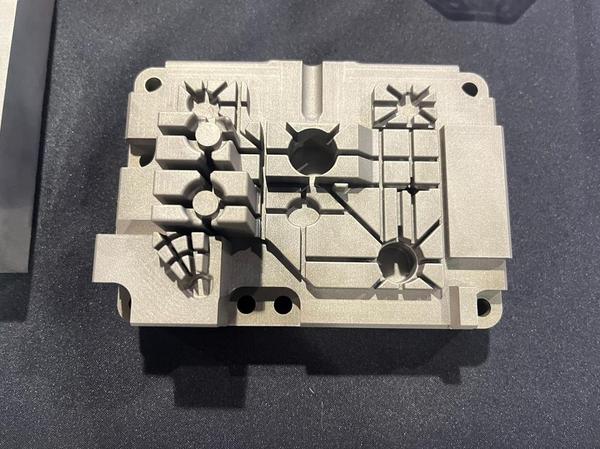

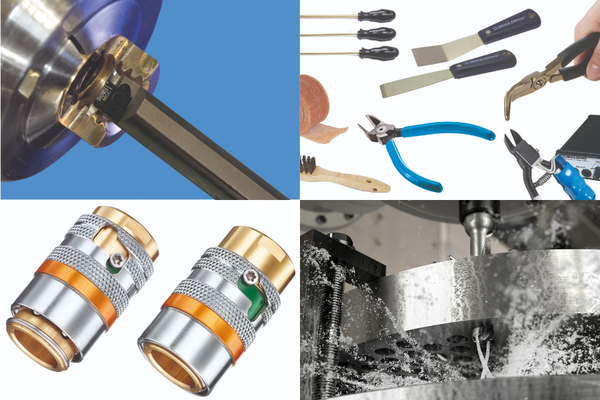

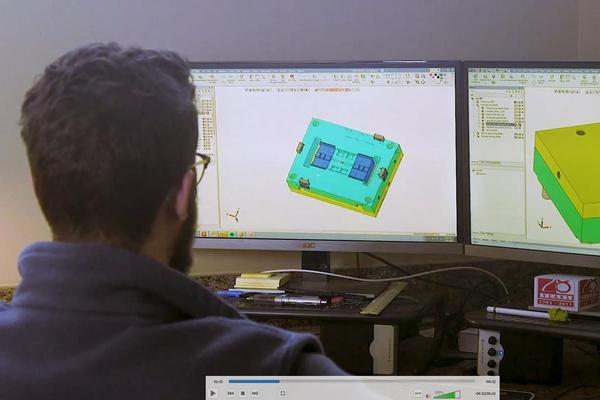

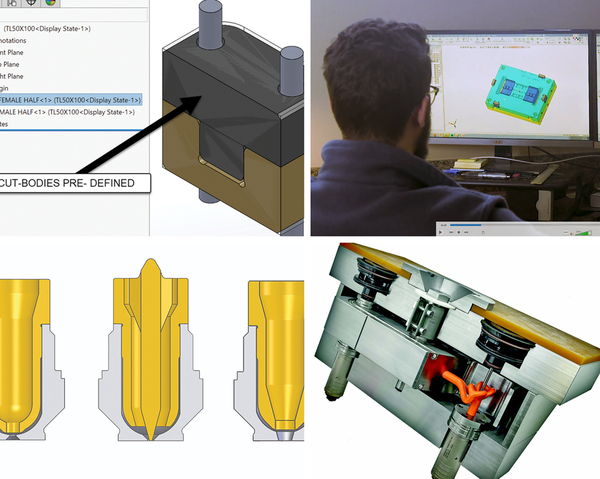

Titan is largely rooted in the agricultural industry. The company utilizes giant steel molds to make large rubber tires for tractors and other vehicles of this nat...

Titan is largely rooted in the agricultural industry. The company utilizes giant steel molds to make large rubber tires for tractors and other vehicles of this nat...